In the fast-paced environment of industrial facilities, maintaining cleanliness and efficiency is crucial for operations. One of the most effective tools in achieving this is the push sweeper. This versatile piece of equipment not only aids in keeping workspaces tidy but also enhances productivity by allowing workers to focus on their tasks rather than waste time on manual clean-up.

However, to fully harness the benefits of a push sweeper, it is essential to implement strategies that maximize its efficiency. In this blog, we will share seven practical tips that can help you optimize the use of push sweepers in your facility. These insights will not only streamline your cleaning processes but also contribute to a safer and more organized working environment, ultimately leading to improved operational flow.

Push sweepers are essential tools in industrial facilities, delivering remarkable benefits that enhance cleanliness and overall operational efficiency. One of the primary advantages of push sweepers is their ability to efficiently remove debris and dirt from large floor areas. Unlike traditional brooms or manual sweeping methods, push sweepers utilize powerful brushes to collect dust, debris, and small particles quickly, significantly reducing the time needed for maintenance. This efficiency is particularly beneficial in settings with high foot traffic or heavy machinery, where cleanliness is paramount to ensure safety and maintain equipment longevity.

In addition to their efficiency, push sweepers also promote a healthier work environment. By minimizing dust and allergens, they contribute to improved air quality, which is essential for the well-being of employees. Furthermore, regular use of push sweepers helps to prevent slip and fall accidents by keeping surfaces clean and free of obstructions. In industrial settings where hygiene standards may be stringent, push sweepers allow for thorough cleaning of surfaces in a way that manual methods cannot match, ensuring compliance with regulatory requirements and fostering a safer workplace.

When selecting the right push sweeper for your industrial facility, it’s essential to consider several key factors that align with your specific operational requirements. First, evaluate the size of your workspace. Larger areas may benefit from wider sweeping paths and larger debris containers to reduce the frequency of emptying, whereas smaller facilities may only require a compact model for maneuverability in tight spaces.

Another critical aspect is the type of surfaces you'll be sweeping. Various models are designed for different terrains, such as concrete, metal, or uneven surfaces. Additionally, think about the nature of the debris you'll encounter. If you regularly deal with heavy particles or fine dust, choosing a sweeper equipped with powerful suction and efficient filtration systems will enhance performance and maintain a cleaner environment.

Finally, consider the ease of use and maintenance—selecting a push sweeper that is ergonomic and easy to operate can greatly improve operator productivity and reduce downtime. By focusing on these factors, you can ensure that you choose the best push sweeper tailored to your facility's needs.

To ensure optimal performance from your push sweepers, regular maintenance is essential. One of the key maintenance tips involves keeping the sweeper's brushes clean. Debris accumulation can significantly reduce cleaning efficiency, so regularly inspect and clean the brushes to maintain their effectiveness. Additionally, check for any wear and tear; replacing worn brushes promptly will ensure that your push sweeper operates at peak performance.

Another crucial aspect of maintenance is to inspect the filters and dust containment systems. Clogged filters can hinder suction and airflow, leading to less effective sweeping. Regularly clean or replace the filters as needed, and ensure that the dust containers are emptied frequently to prevent overflow. By adhering to these essential maintenance practices, you can maximize the efficiency and longevity of your push sweepers, ultimately contributing to a cleaner and safer industrial environment.

| Tip | Description | Frequency of Maintenance | Expected Impact |

|---|---|---|---|

| Regular Brush Inspection | Check brushes for wear and replace as needed to ensure optimal sweeping. | Weekly | Improved cleaning efficiency. |

| Debris Collection Check | Ensure the debris container is emptied regularly to maintain performance. | Daily | Consistent sweeping effectiveness. |

| Battery Maintenance | Regularly check battery levels and connections for optimal power supply. | Monthly | Prolonged equipment lifespan. |

| Filter Replacement | Replace filters to ensure proper air flow and dust control. | Every 6 months | Better air quality and performance. |

| Checking Wheels and Tires | Inspect wheels for wear and ensure proper inflation for smooth operation. | Monthly | Enhanced maneuverability and speed. |

| Chassis Cleaning | Clean the chassis regularly to prevent buildup of dirt and debris. | Weekly | Prevents rust and damage to components. |

| User Training | Provide training for operators to ensure proper handling and operation of the sweeper. | As needed | Increased safety and efficiency. |

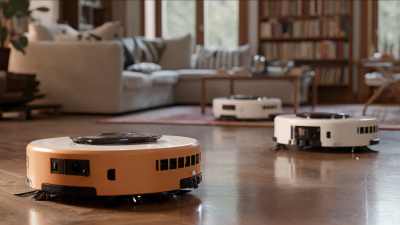

In modern industrial facilities, the efficiency of push sweepers can significantly impact overall productivity. One effective technique to enhance the performance of push sweepers during operation is to incorporate advanced cleaning technologies that are becoming more prevalent in the market. For instance, recent trends indicate a rise in the adoption of automatic and robotic cleaning solutions, which can streamline the cleaning process, reduce manual labor, and increase operational efficiency.

According to industry reports, implementing autonomous devices can lead to a reduction in cleaning time by up to 30%, allowing workers to focus on more critical tasks.

Additionally, optimizing the design of push sweepers to improve dust collection capabilities is crucial. Recent studies have shown the importance of maintaining clean surfaces in industrial settings, with dust accumulation potentially reducing equipment efficiency by as much as 15%. By integrating vacuum enhancement technologies, such as improved suction systems or specialized brush designs, operators can maximize the efficacy of push sweepers, ensuring thorough cleaning while minimizing downtime.

Adopting these techniques not only improves performance but also contributes to enhanced safety and operational reliability within the facility, ultimately leading to greater productivity.

Training your staff for effective use of push sweepers is vital for maximizing efficiency in any industrial facility. According to a recent industry report by the Cleaning Association, facilities that invest in staff training can enhance their cleaning efficiency by up to 30%. This is achieved when operators are well-versed in the equipment’s features and maintenance requirements, ensuring the push sweepers operate at peak performance throughout their lifespan.

Moreover, effective training programs should include hands-on demonstrations and safety protocols to minimize the risk of accidents. A study by the Occupational Safety and Health Administration (OSHA) revealed that workplaces with comprehensive training experience a 50% reduction in equipment-related injuries. By empowering employees with the proper knowledge and skills to operate push sweepers, facilities not only improve productivity but also create a safer workspace.

To maximize the benefits of push sweepers, ongoing training and refresher courses should be implemented to keep staff updated on best practices and innovations in cleaning technology.